Oil Mist Collector with Air Cleaner

When the machining process is in high speed and cutting, the oil gas generated from coolants is increased. If it spreads to the operation area, it will cause the air pollution and seriously harm to human health. Furthermore, machinery which stays in oil smoke for a long time would be brought about high failure. CTM’s new creative Oil Mist Collector with Air Cleaner can solve these problems.

Installation of air cleaner on your machine or in your factory is capable of effectively recycling oil mist for reuse. It not only avoids toxic matter extending and keeps cleanliness of working environment, but it also raises working efficiency and maintains your personal health. Meanwhile, it can cut down the cost, save energy, save time of cleaning, and improve the quality of air and environment. It is the best company for the machinery and processing industries.

Description

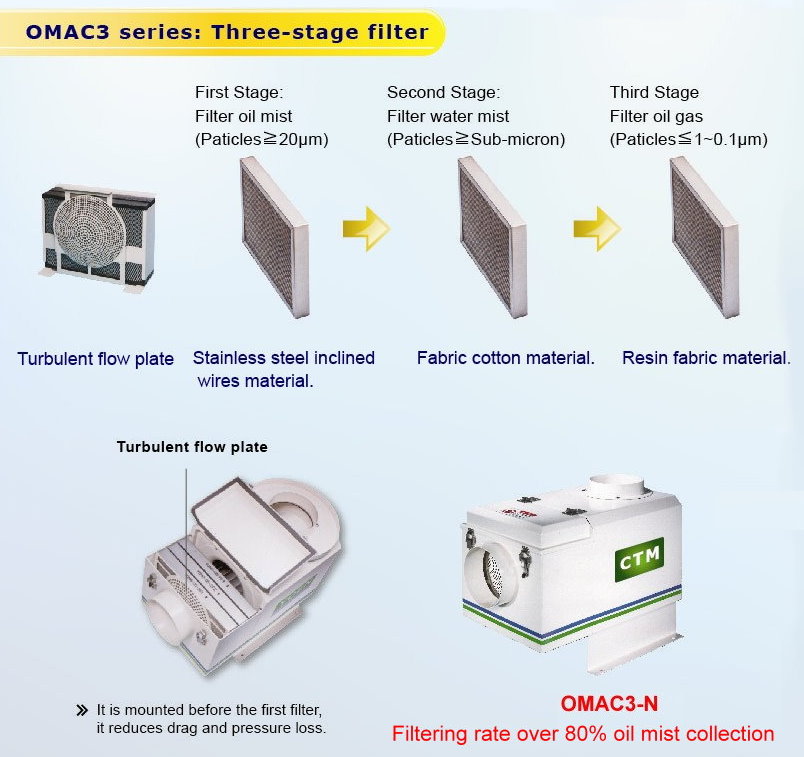

OMAC3 series

CTM’s Oil Mist Collector has three-stage filtering system.

- The first filter screen is a woven stainless steel screen, cable of filtering oil mist (filtering particle≧20μm).

- The second filter screen is fabric cotton, which can leach the water mist (filtering particle≧ sub-micron).

- The third is the filtration cartridge, which is able to filter oil smoke (filtering particle≦ 0.01μm).

This exclusively designed filtering system is capable of thoroughly reducing oil mist, also offers a uniqueair purification function.The Oil Mist Collector with Air Cleaner "consumes less electricity, while providing maximum oil mist suction performance".

Our design concept is "Environmental Production & Energy Reclamation", "Save Energy & Reduce Carbon" and "Air Purification". Air cleaners employ washable filter system and environment protected materials. They feature extra high oil mist collection efficiency up to 99% for reuse, contributing to environmental protection and energy reclamation. On aspect of save energy & reduce carbon, with the low power consumed and high efficiency operation system, electricity consumption and carbon dioxide discharge can be reduce to meet the international trend of energy-saving and carbon reduction.

OMAC4 series (For Water Based Coolant)

CTM’s Oil Mist Collector has four-stage filtering system.

- The first filter screen is a woven stainless steel screen, cable of filtering oil mist (filtering particle≧20μm).

- The second filter screen is fabric cotton, which can leach the water mist (filtering particle≧ sub-micron).

- The third is the filtration cartridge, which is able to filter oil smoke (filtering particle≦ 0.01μm).

- The forth is the filtration cartridge, which is able to filter oil smoke (filtering particle≦ 0.01μm).

This exclusively designed filtering system is capable of thoroughly reducing oil mist, also offers a uniqueair purification function.The Oil Mist Collector with Air Cleaner "consumes less electricity, while providing maximum oil mist suction performance".

Our design concept is "Environmental Production & Energy Reclamation", "Save Energy & Reduce Carbon" and "Air Purification". Air cleaners employ washable filter system and environment protected materials. They feature extra high oil mist collection efficiency up to 99% for reuse, contributing to environmental protection and energy reclamation. On aspect of save energy & reduce carbon, with the low power consumed and high efficiency operation system, electricity consumption and carbon dioxide discharge can be reduce to meet the international trend of energy-saving and carbon reduction.

With the outstanding function of isolating oil mist, powder dust, toxic gas, and odors to purify air in the working environment, on air purification side.

OMAC4-A series (For Oil Based Coolant+ Oil Fumes)

CTM’s Oil Mist Collector has four-stage filtering system.

- The first filter screen is a woven stainless steel screen, cable of filtering oil mist (filtering particle≧20μm).

- The second filter screen is fabric cotton, which can leach the water mist (filtering particle≧ sub-micron).

- The third is the filtration cartridge, which is able to filter oil smoke (filtering particle≦ 0.01μm).

- The forth is the filtration cartridge, which is able to filter oil smoke (filtering particle≦ 0.01μm).

This exclusively designed filtering system is capable of thoroughly reducing oil mist, also offers a uniqueair purification function.The Oil Mist Collector with Air Cleaner "consumes less electricity, while providing maximum oil mist suction performance".

Our design concept is "Environmental Production & Energy Reclamation", "Save Energy & Reduce Carbon" and "Air Purification". Air cleaners employ washable filter system and environment protected materials. They feature extra high oil mist collection efficiency up to 99% for reuse, contributing to environmental protection and energy reclamation. On aspect of save energy & reduce carbon, with the low power consumed and high efficiency operation system, electricity consumption and carbon dioxide discharge can be reduce to meet the international trend of energy-saving and carbon reduction.

With the outstanding function of isolating oil mist, powder dust, toxic gas, and odors to purify air in the working environment, on air purification side.

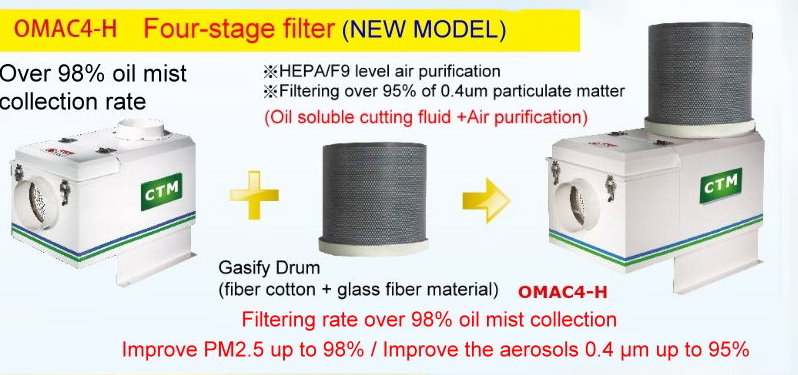

[NEW] OMAC4-H series (For Oil Based Coolant+ Oil Fumes)

CTM’s Oil Mist Collector has four-stage filtering system.

- The first filter screen is a woven stainless steel screen, cable of filtering oil mist (filtering particle≧20μm).

- The second filter screen is fabric cotton, which can leach the water mist (filtering particle≧ sub-micron).

- The third is the filtration cartridge, which is able to filter oil smoke (filtering particle≦ 0.01μm).

- The forth is the filtration cartridge, which is able to filter oil smoke (filtering particle≦ 0.01μm).

This exclusively designed filtering system is capable of thoroughly reducing oil mist, also offers a uniqueair purification function.The Oil Mist Collector with Air Cleaner "consumes less electricity, while providing maximum oil mist suction performance".

Our design concept is "Environmental Production & Energy Reclamation", "Save Energy & Reduce Carbon" and "Air Purification". Air cleaners employ washable filter system and environment protected materials. They feature extra high oil mist collection efficiency up to 99% for reuse, contributing to environmental protection and energy reclamation. On aspect of save energy & reduce carbon, with the low power consumed and high efficiency operation system, electricity consumption and carbon dioxide discharge can be reduce to meet the international trend of energy-saving and carbon reduction.

With the outstanding function of isolating oil mist, powder dust, toxic gas, and odors to purify air in the working environment, on air purification side.

Applicable Range

CNC digital control machine, cutting machine, electric discharge machine, gear-hobbing machine, grinding machine, screw heading machine and any machine would produce oil gas

Specification

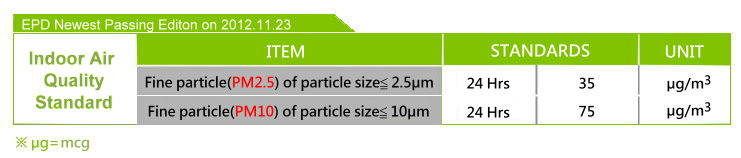

Indoor Air Quality Standard

OMAC3 series ( Three-stage filter)

| Model | Unit | OMAC3-10N | OMAC3-15N | OMAC3-20N | OMAC3-30N |

|---|---|---|---|---|---|

| Motor | KW | 0.18 | 0.37 | 0.56 | 0.75 |

| Voltage | V/HZ | 3Φ 220V / 380V / 60Hz / 50Hz | |||

| Speed | rpm | 3400rpm/ 2900rpm | |||

| Air Flow Rate | m³/min | 15/ 14 | 20/ 18 | 25/ 22 | 31/ 27 |

| Dimension | mm(LxWxH) | 660x330x475 | 675x350x508 | 780x390x534 | 804x420x561 |

| Weight | kg | 31.2 | 34.2 | 40.4 | 48 |

OMAC4 series (For Water Based Coolant) ( Four-stage filter)

| Model | Unit | OMAC4-10Y | OMAC4-15Y | OMAC4-20Y | OMAC4-30Y |

|---|---|---|---|---|---|

| Motor | KW | 0.18 | 0.37 | 0.56 | 0.75 |

| Voltage | V/HZ | 3Φ 220V / 380V / 60Hz / 50Hz | |||

| Speed | rpm | 3400rpm/ 2900rpm | |||

| Air Flow Rate | m³/min | 16/ 14 | 21/ 19 | 26/ 23 | 32/ 27 |

| Dimension | mm(LxWxH) | 660x350x749 | 675x350x782 | 780x390x812 | 804x439x1089 |

| Weight | kg | 36 | 38.4 | 45 | 55 |

OMAC4-A series (For Oil Based Coolant+ Oil Fumes) ( Four-stage filter)

| Model | Unit | OMAC4-15A | OMAC4-15A | OMAC4-30A | |

|---|---|---|---|---|---|

| Motor | KW | 0.37 | 0.56 | 0.75 | |

| Voltage | V/HZ | 3Φ 220V / 380V / 60Hz / 50Hz | |||

| Speed | rpm | 3400rpm/ 2900rpm | |||

| Air Flow Rate | m³/min | 21/ 17 | 26/ 21 | 30/ 25 | |

| Dimension | mm(LxWxH) | 660x350x1080 | 780x390x1108 | 804x439x1139 | |

| Weight | kg | 42.8 | 49 | 59 | |

[NEW] OMAC4-H series (For Oil Based Coolant+ Oil Fumes) ( Four-stage filter)

| Model | Unit | OMAC4-10H | OMAC4-15H | OMAC4-20H | |

|---|---|---|---|---|---|

| Motor | KW | 0.18 | 0.37 | 0.56 | |

| Voltage | V/HZ | 3Φ 220V / 380V / 60Hz / 50Hz | |||

| Speed | rpm | 3400rpm/ 2900rpm | |||

| Air Flow Rate | m³/min | 15/ 12 | 20/ 16 | 25/ 20 | |

| Dimension | mm(LxWxH) | 660x350x749 | 675x350x780 | 780x390x813 | |

| Weight | kg | 36.4 | 39.6 | 45.8 | |

OMAC3

OMAC3 OMAC4

OMAC4 OMAC4-A

OMAC4-A OMAC4-H

OMAC4-H